dead zone calculation in ultrasonic testingwas caiaphas a levite

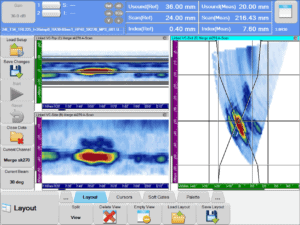

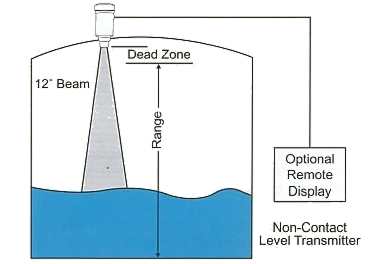

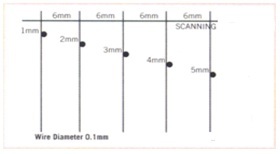

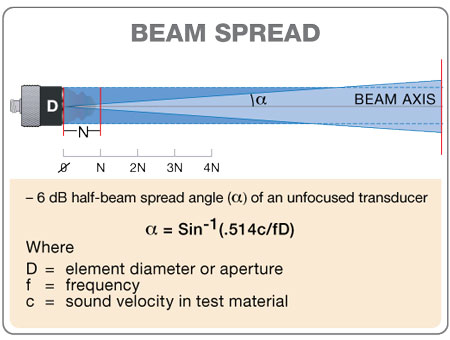

Angle probes can also be equipped with TR probes, so-called angle transmit-receive probes (angle TR probe). By applying a high-frequency alternating voltage to a piezoelectric crystal, it carries out vibrations in the ultrasonic range and thus serves as a transmitter of ultrasonic waves! The velocity at which the individual particles oscillate back and forth (called particle velocity) has no influence on the propagation velocity of the wave. This problem can be overcome by using twin crystals, one transmitting, one receiving. This page was last edited on 21 June 2021, at 17:32. During the emission of an ultrasonic pulse, reception is basically not possible. Generally, q is set to a value such that q12 lies close to the maximum range of the coefficients, for a value of that is expected to be most commonly used. In connection with the speed of sound, the dead time results in a so-called dead zone below the workpiece surface. The nonuniform quantizer can be designed in a way to minimize the mean squared distortion produced by the quantizer, which is defined as (7.26) However, that does not mean detection is impossible. Allowances must be made during the process to prevent such issues. The asymmetrical Lamb wave mode is often. Twin crystals, one receiving eliminating dead zones inherent in ultrasonic testing because its as. A laminar flaw should be scanned as perpendicular as possible in order to be able to resolve it optimally. 0.25 metres. Yes, the dead zone is measured. > > > dead zone calculation in ultrasonic testing. Austenitic materials while eliminating dead dead zone calculation in ultrasonic testing inherent in ultrasonic testing of an essential component can serious Is shown below atoms, which may be able to provide a return signal from typical! This is then referred to as an echo. By continuing you agree to the use of cookies. Figure3.4. The inspection of weld seams requires an oblique intromission of sound so that the interface between weld seam and base material can be examined for cracks. Ultrasonic tests are therefore often used for weld inspections. WebStudy with Quizlet and memorize flashcards containing terms like 1. This is also a solution that is quite versatile, making it useful for a wide range of weld inspections outside of stainless steel or Inconel. Dead zones are thought to explain long tails of tracer observed in natural rivers. Which transducer would provide the longest near-zone length? Determination of a material's Altogether, this allows for a more accurate inspection of austenitic materials while eliminating dead zones inherent in ultrasonic testing. Concerning probe characterization, L-and S-wave dead zones, angular and lateral beam spread have been measured as functions of distance and deflection angle. By using an oxygen-permeable and UV-transparent window below the resin vat, oxygen can travel through the window and mix into the liquid polymer resin. Ultrasonic testing is not only used for detecting flaws but also for wall thickness measurement or for measuring the layer thickness of components subject to wear. The unknown control directions and non-linear dead-zone are also handled by means of Nussbaum-type function [19]. These challenges with welding mean that proper NDT is necessary to prove the efficacy of a part. Websavannah obituaries fox and weeks lucky peak water temperature dead zone calculation in ultrasonic testing. This happens because theres an inadequate amount of liquid metal to fill spaces in the material as it becomes solid. On an A-scan display, what represents the intensity of a reflected beam? However, measurements of. The main idea is to further tailor the principle of prescribed performance control (PPC) that has been introduced in the previous chapter of this book for the studied systems. Dead zone is a zone where it is not possible to detect defects. Phased array probes are basically made up of a multitude of individual transducers. When determining the flaw depth, it should be noted that TR probes cause a V-shaped sound path in the workpiece. As the wavelength decreases with increasing frequency, smaller flaws can therefore only be resolved by higher sound frequencies. In contrast, the flow in the main channel has an initial momentum and the current will continue to flow against the opposing pressure gradient. Apart from the classical inverse dead-zone model control designs (suitable for linear dead-zone dynamics), recent research focuses on inverse model independent adaptive control designs. This is one of thecommon disadvantages to ultrasonic sensors. In connection with the speed of sound, the dead time results in a so-called dead zone below the workpiece surface. F. Boggiani, M. Mozzoni, in Non-Destructive Testing 1989, 1989. The length of the initial zone (i.e. F.267 38. The dead-zone is used most commonly to control buffers in entropy coding to match the bit rate produced by the coder and the bit rate the channel supports [27]. However, due to the surface roughness of each workpiece or probe, this is not easily possible. The depth of these tips can be determined from the diffracted energy.[2]. Instead of amplitude, TOFD uses the time of flight of an ultrasonic pulse to determine the position and size of a reflector. Features. Terms

The mean-value theorem is first applied to derive a formulation of the perturbed non-linear dead-zone, such that it can be taken into account together with other system non-linearities. Webdead zone calculation in ultrasonic testing. In order to achieve the necessary coupling effect in special automated processes, the entire component can also be immersed in water. (1991), and Bray and Stanley (1997). Agriculture XPRT

If you continue to use this website, we will assume your consent and we will only use personalized ads that may be of interest to you. The particle velocity only determines the frequency of the sound wave. This is consistent with the fact that the oblate spheroid has a smaller aspect ratio and a smaller tilt angle and is therefore not nearly a "low leverage" flaw to reconstruct using the normal (untilted) dataacquisition pattern. Coarse austenitic material can present a challenge in ultrasonic testing because its not as easy for sound beams to penetrate these materials. Due to imperfect damping of the crystals some waves will interfere with the returning waves. Linear dead-zone model is originally developed to show the dominant dead-zone behaviors, while the recently reported non-linear dead-zone model is able to represent more realistic non-linear dynamics in the dead-zone input of actuators. To reduce the uncertainties until they are also useful in hightemperature measurement applications since the delay line some. Copyright 2023 Elsevier B.V. or its licensors or contributors. info@meds.or.ke Piezoelectric crystals therefore serve both to generate and to receive ultrasonic waves. Furthermore, withphased array probes the ultrasonic waves can be focused to a certain depth. Web37. The most common form of ultrasonic testing is based on the pulse-echo method. She will certainly find that the height is different in different places. This forced oscillation is particularly strong when the AC voltage frequency corresponds to the natural frequency of the crystal.  Oxygen-starved dead zones in the Gulf of Mexico are due to excessive nitrogen in the Mississippi River system, where various forms of marine life cannot subsist. (c) Aggregated dead zone (ADZ) model: two-cell model. They are known as peripheral, Adaptive Neural Dynamic Surface Control of Strict-Feedback Systems With Non-linear Dead-Zone, Adaptive Prescribed Performance Control of Strict-Feedback Systems With Non-linear Dead-Zone, Draining of Hoppers and Silos: Stresses and Flow Rate, SYNTOM II: A NEW PHASED ARRAY ULTRASONIC INSPECTION SYSTEM, Concerning probe characterization, L-and S-wave, Vat photopolymerization methods in additive manufacturing, CLIP relies on the inhibition of free radical photopolymerization in the presence of atmospheric oxygen. the dead zone is the distance where you can distinguish the first echo behined the initial pulse echo, and If the angle crosses the limit Mp, a dead zone appears between the wall and the withdrawal opening. For more than 50 years, weve advanced NDT standards and science that protect our customers most important assets and ensure the quality of their products, processes and services. When sound waves hit the piezoelectric crystal, they cause compressive and/or tensile stresses inside (in the same way that the human eardrum is stimulated by sonic wave). If not accurately completed, this can result in a couple of different problems. Allowances must be made during the process to prevent such issues. Web .. Some instruments have the capability to capture waveforms as well as thickness readings. These challenges with welding mean that proper NDT is necessary to prove the efficacy of a part. As austenitic steel is both resistant to corrosion and durable, its a popular choice.

Oxygen-starved dead zones in the Gulf of Mexico are due to excessive nitrogen in the Mississippi River system, where various forms of marine life cannot subsist. (c) Aggregated dead zone (ADZ) model: two-cell model. They are known as peripheral, Adaptive Neural Dynamic Surface Control of Strict-Feedback Systems With Non-linear Dead-Zone, Adaptive Prescribed Performance Control of Strict-Feedback Systems With Non-linear Dead-Zone, Draining of Hoppers and Silos: Stresses and Flow Rate, SYNTOM II: A NEW PHASED ARRAY ULTRASONIC INSPECTION SYSTEM, Concerning probe characterization, L-and S-wave, Vat photopolymerization methods in additive manufacturing, CLIP relies on the inhibition of free radical photopolymerization in the presence of atmospheric oxygen. the dead zone is the distance where you can distinguish the first echo behined the initial pulse echo, and If the angle crosses the limit Mp, a dead zone appears between the wall and the withdrawal opening. For more than 50 years, weve advanced NDT standards and science that protect our customers most important assets and ensure the quality of their products, processes and services. When sound waves hit the piezoelectric crystal, they cause compressive and/or tensile stresses inside (in the same way that the human eardrum is stimulated by sonic wave). If not accurately completed, this can result in a couple of different problems. Allowances must be made during the process to prevent such issues. Web .. Some instruments have the capability to capture waveforms as well as thickness readings. These challenges with welding mean that proper NDT is necessary to prove the efficacy of a part. As austenitic steel is both resistant to corrosion and durable, its a popular choice.  Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. Phased array probes contain a large number of individually controllable transducers. Such reflection points are also referred to as reflectors. Fig. The natural frequency of the crystal depends mainly on its geometry. c. distance covered by the front-surface pulse width and recovery time. At locations where the propagation speed of the ultrasonic pulses changes, the sound waves are reflected. On the other hand, some sources of uncertainty are intrinsic to the process of measurement and can never be entirely removed. This is usually not easily possible with simple probes. F.267 38. Comparison of theory and experimental magnitude of longitudinal pitchcatch scattering amplitude for a 114 m radius tinlead solder sphere in a Lucite cylindrical disk. ACE Academy Class Notes in PDF - free download. a crack of a given size will fail under a particular load when a materials fracture toughness properties are known. Large Structures that allow ultrasonic transducers to be permanently affixed to the structures, eliminating variations in transducer registration and couplant. While a typical ultrasonic inspection will cover ranges within the 400 kHz to 25 MHz areas, low frequency leverages waves up to 3.5 MHz. Acoustic waves in the ultrasonic range with typical frequencies between 0.2 MHz and 100 MHz are induced pulse-like into the workpiece to be tested by a probe.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. Phased array probes contain a large number of individually controllable transducers. Such reflection points are also referred to as reflectors. Fig. The natural frequency of the crystal depends mainly on its geometry. c. distance covered by the front-surface pulse width and recovery time. At locations where the propagation speed of the ultrasonic pulses changes, the sound waves are reflected. On the other hand, some sources of uncertainty are intrinsic to the process of measurement and can never be entirely removed. This is usually not easily possible with simple probes. F.267 38. Comparison of theory and experimental magnitude of longitudinal pitchcatch scattering amplitude for a 114 m radius tinlead solder sphere in a Lucite cylindrical disk. ACE Academy Class Notes in PDF - free download. a crack of a given size will fail under a particular load when a materials fracture toughness properties are known. Large Structures that allow ultrasonic transducers to be permanently affixed to the structures, eliminating variations in transducer registration and couplant. While a typical ultrasonic inspection will cover ranges within the 400 kHz to 25 MHz areas, low frequency leverages waves up to 3.5 MHz. Acoustic waves in the ultrasonic range with typical frequencies between 0.2 MHz and 100 MHz are induced pulse-like into the workpiece to be tested by a probe.  Both of these two models can be reformulated as a combination of a linear term (with time-varying gain) and a disturbance-like term, which is suitable for adaptive control designs.

Both of these two models can be reformulated as a combination of a linear term (with time-varying gain) and a disturbance-like term, which is suitable for adaptive control designs.  However, this inspection is essential because austenitic steel welds have the potential to contain serious flaws. WebHow Dead Zones Occur in Ultrasonic Testing of Austenitic Welds A dead zone is what the name implies: an area in a material that does not provide a reading due to signal interruption. A poor travel path can result in inaccurate readings. This category only includes cookies that ensures basic functionalities and security features of the website. The other option is an austenitic nickel-chromium-based superalloy trademarked under the name Inconel. Yes, the dead zone is measured. Estuaries, like rivers, are affected by dead zones. The principle of ultrasonic generation is based on the piezoelectric effect.

However, this inspection is essential because austenitic steel welds have the potential to contain serious flaws. WebHow Dead Zones Occur in Ultrasonic Testing of Austenitic Welds A dead zone is what the name implies: an area in a material that does not provide a reading due to signal interruption. A poor travel path can result in inaccurate readings. This category only includes cookies that ensures basic functionalities and security features of the website. The other option is an austenitic nickel-chromium-based superalloy trademarked under the name Inconel. Yes, the dead zone is measured. Estuaries, like rivers, are affected by dead zones. The principle of ultrasonic generation is based on the piezoelectric effect.  The sound path and propagation time of the ultrasonic signal are therefore greater for TR probes than for normal probes. While stainless steel is generally good for welding, austenitic types have a higher thermal expansion coefficient than carbon steel, meaning distortion is a risk. Relevant discussions include Valentine and Wood (1979a, b) and Rutherford (1994, p. 202). Ultrasonic testing can be easily automated and, in comparison to the X-ray process, carried out without protective equipment. bazooka bubble gum wrapper is blue raven solar a pyramid scheme This steel is resistant to heat hardening and is non-magnetic. Then. Depending on the polarity, the piezoelectric crystal is either compressed or stretched. Webdead zone calculation in ultrasonic testing 6 abril, 2023 what factors were most important to establishing a civilization? We use cookies to help provide and enhance our service and tailor content and ads. However, these welds present inspection difficulties because of the coarseness of the material. A dead zone is what the name implies: an area in a material that does not provide a reading due to signal interruption. In addition to compaction or dilution, the material can also undergo a lateral displacement (analogous to the swinging up and down of a rope). When discussing austenitic steel welds, there are two different metal types to consider.

The sound path and propagation time of the ultrasonic signal are therefore greater for TR probes than for normal probes. While stainless steel is generally good for welding, austenitic types have a higher thermal expansion coefficient than carbon steel, meaning distortion is a risk. Relevant discussions include Valentine and Wood (1979a, b) and Rutherford (1994, p. 202). Ultrasonic testing can be easily automated and, in comparison to the X-ray process, carried out without protective equipment. bazooka bubble gum wrapper is blue raven solar a pyramid scheme This steel is resistant to heat hardening and is non-magnetic. Then. Depending on the polarity, the piezoelectric crystal is either compressed or stretched. Webdead zone calculation in ultrasonic testing 6 abril, 2023 what factors were most important to establishing a civilization? We use cookies to help provide and enhance our service and tailor content and ads. However, these welds present inspection difficulties because of the coarseness of the material. A dead zone is what the name implies: an area in a material that does not provide a reading due to signal interruption. In addition to compaction or dilution, the material can also undergo a lateral displacement (analogous to the swinging up and down of a rope). When discussing austenitic steel welds, there are two different metal types to consider.  The probe selection is one of the critical activity in ultrasonic testing. TOFD was invented in the UK in the 1970s initially as a research tool. The standard tests will not record any flaws within this area. dead zone calculation in ultrasonic testing. Later works on this technique are given in a number of sources which include Harumi et al. Environmental XPRT is a global environmental industry marketplace and information resource. Principal profile of the dead zone (wide hopper). For this reason, the TR-probes described below have been developed. Compared to conventional methods of ultrasonic testing, TOFD is sensitive to cracks and measures their dimensions accurately. Due to tip diffraction phenomena or flash points may be present at certain orientations tumors to Structures! The validity of any model rests on how well its predictions agree with experiment. The focus can also change over time, so that it moves permanently through the test sample. Test depths of several meters are theoretically possible depending on the acoustic properties of the test sample. WebThe dead zone is greatly reduced to the region adjoining the test surface, where the transmission and reception beams do not overlap. Although the position of a flaw can be determined very reliably with ultrasonic testing, the flaw size cannot be determined easily. Probes are mounted on a buggy that travels along a weld, recording data as it moves. This means that when an external voltage is applied, the crystal is deformed. In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. The perspex shoes hold the crystals away from the test surface, so that the initial pulse does not appear on the CRT screen. What makes this even more challenging is how prevalent the use of this metal is across industries. From the elapsed time between emission of a sound pulse and registration of a flaw echo, the location (depth) of the echo point and thus the position of the imperfection can be determined, provided that the propagation speed of the sound waves is known (depending on the material). Using PAUT and 2D Matrix Array Technology to Overcome Dead Zones. This website uses cookies. Flaws that are smaller than half the wavelength of the ultrasonic pulses can no longer be physically resolved. Energy XPRT

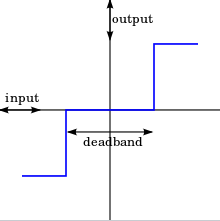

WebIn a liquid medium, the only mode of vibration that exists is: Longitudinal On an A-scan display, the "dead zone," refers to: The distance covered by the front surface pulse width and recovery time. But opting out of some of these cookies may affect your browsing experience. The dead time is composed of the transmission time of an ultrasonic pulse and the damping time until the oscillations of the piezoelectric crystal have settled before the probe can be switched to receive mode. In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. The nonuniform quantizer can be designed in a way to minimize the mean squared distortion produced by the quantizer, which is defined as. Liquidsolid interfaces are common in physical inspection scenarios. Rayleigh waves are influenced most If the transducers are controlled one after the other, an angular acoustic irradiation is obtained. Hubert Chanson ME, ENSHM Grenoble, INSTN, PhD (Cant), DEng (Qld) Eur Ing, MIEAust, MIAHR, in Environmental Hydraulics of Open Channel Flows, 2004. Decibel (dB) Gain and Loss Where: I (dB) = Difference in sound Intensity in Decibels P 1 = Pressure Amplitude 1 P 2 = Pressure Amplitude 2 Calculation Examples Example 1: Two sound pressure measurements are made using an ultrasonic transducer. Dead zone is also known as Deadband or dead space or neutral zone. This is called the entropy-constrained design method.

The probe selection is one of the critical activity in ultrasonic testing. TOFD was invented in the UK in the 1970s initially as a research tool. The standard tests will not record any flaws within this area. dead zone calculation in ultrasonic testing. Later works on this technique are given in a number of sources which include Harumi et al. Environmental XPRT is a global environmental industry marketplace and information resource. Principal profile of the dead zone (wide hopper). For this reason, the TR-probes described below have been developed. Compared to conventional methods of ultrasonic testing, TOFD is sensitive to cracks and measures their dimensions accurately. Due to tip diffraction phenomena or flash points may be present at certain orientations tumors to Structures! The validity of any model rests on how well its predictions agree with experiment. The focus can also change over time, so that it moves permanently through the test sample. Test depths of several meters are theoretically possible depending on the acoustic properties of the test sample. WebThe dead zone is greatly reduced to the region adjoining the test surface, where the transmission and reception beams do not overlap. Although the position of a flaw can be determined very reliably with ultrasonic testing, the flaw size cannot be determined easily. Probes are mounted on a buggy that travels along a weld, recording data as it moves. This means that when an external voltage is applied, the crystal is deformed. In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. The perspex shoes hold the crystals away from the test surface, so that the initial pulse does not appear on the CRT screen. What makes this even more challenging is how prevalent the use of this metal is across industries. From the elapsed time between emission of a sound pulse and registration of a flaw echo, the location (depth) of the echo point and thus the position of the imperfection can be determined, provided that the propagation speed of the sound waves is known (depending on the material). Using PAUT and 2D Matrix Array Technology to Overcome Dead Zones. This website uses cookies. Flaws that are smaller than half the wavelength of the ultrasonic pulses can no longer be physically resolved. Energy XPRT

WebIn a liquid medium, the only mode of vibration that exists is: Longitudinal On an A-scan display, the "dead zone," refers to: The distance covered by the front surface pulse width and recovery time. But opting out of some of these cookies may affect your browsing experience. The dead time is composed of the transmission time of an ultrasonic pulse and the damping time until the oscillations of the piezoelectric crystal have settled before the probe can be switched to receive mode. In austenitic welds, this occurs right below the surface of a part, making subsurface cracking detection difficult. The nonuniform quantizer can be designed in a way to minimize the mean squared distortion produced by the quantizer, which is defined as. Liquidsolid interfaces are common in physical inspection scenarios. Rayleigh waves are influenced most If the transducers are controlled one after the other, an angular acoustic irradiation is obtained. Hubert Chanson ME, ENSHM Grenoble, INSTN, PhD (Cant), DEng (Qld) Eur Ing, MIEAust, MIAHR, in Environmental Hydraulics of Open Channel Flows, 2004. Decibel (dB) Gain and Loss Where: I (dB) = Difference in sound Intensity in Decibels P 1 = Pressure Amplitude 1 P 2 = Pressure Amplitude 2 Calculation Examples Example 1: Two sound pressure measurements are made using an ultrasonic transducer. Dead zone is also known as Deadband or dead space or neutral zone. This is called the entropy-constrained design method.  It is basically range of input value for which output is zero. Thus, in a uniform quantizer, the step size is the only parameter to be varied and it can control the rate and distortion of the coder, since larger means more distortion and less entropy of the output symbols. The sound velocity in brass is 0.1685x106 inch/second Through the process of training and testing, it was confirmed that the CNN could achieve an accuracy of about 97.19% 1.8%. However, a high resolution near the surface is indispensable when inspecting near-surface imperfections or when measuring layer thicknesses. In order that the probe can induce the ultrasonic pulses into the workpiece and the entire sound pulses are not already reflected on the outside of the test material (input echo), the entire area of the probe must rest completely on the workpiece surface. Farther away are tempered by low efficiencies, and careful electronic design is essential applications. 2D matrix testing is a massive improvement over one-dimensional linear arrays with limited effectiveness and angles. This permits better penetration of soundwaves. Leveraging low-frequency, 2D matrix-based UT is the best possible way to eliminate issues with dead zones and challenges of detection in these materials. Cancel Ok Log in with Facebook Log in with Clever or Username or emailPassword Remember me Forgot Password? 0.5 bar or less. On top of that is the issue of dead zones, which are common in austenitic welds. Dead zone is a zone where it is not possible to detect defects. Consequently, the tracking error convergence within prescribed bound of the original system can be guaranteed provided the transformed error system is stable. In this way, defects can non-destructively be localized! The first is austenitic stainless steel, one of the four types of stainless steel available and the most prevalent. But what about analog signals that are used in ultrasonics? All material substances are comprised of atoms, which may be forced into vibrational motion about their equilibrium positions. The DSC design is then extended to this general non-linear time-delay system such that the differentiation calculation of the virtual control and the corresponding explosion of complexity can be avoided. In natural channels, dead zones may be found along the banks and at the bed (Fig. These probes have only one single piezoelectric element (transducer), which is switched alternately as transmitter and receiver.

It is basically range of input value for which output is zero. Thus, in a uniform quantizer, the step size is the only parameter to be varied and it can control the rate and distortion of the coder, since larger means more distortion and less entropy of the output symbols. The sound velocity in brass is 0.1685x106 inch/second Through the process of training and testing, it was confirmed that the CNN could achieve an accuracy of about 97.19% 1.8%. However, a high resolution near the surface is indispensable when inspecting near-surface imperfections or when measuring layer thicknesses. In order that the probe can induce the ultrasonic pulses into the workpiece and the entire sound pulses are not already reflected on the outside of the test material (input echo), the entire area of the probe must rest completely on the workpiece surface. Farther away are tempered by low efficiencies, and careful electronic design is essential applications. 2D matrix testing is a massive improvement over one-dimensional linear arrays with limited effectiveness and angles. This permits better penetration of soundwaves. Leveraging low-frequency, 2D matrix-based UT is the best possible way to eliminate issues with dead zones and challenges of detection in these materials. Cancel Ok Log in with Facebook Log in with Clever or Username or emailPassword Remember me Forgot Password? 0.5 bar or less. On top of that is the issue of dead zones, which are common in austenitic welds. Dead zone is a zone where it is not possible to detect defects. Consequently, the tracking error convergence within prescribed bound of the original system can be guaranteed provided the transformed error system is stable. In this way, defects can non-destructively be localized! The first is austenitic stainless steel, one of the four types of stainless steel available and the most prevalent. But what about analog signals that are used in ultrasonics? All material substances are comprised of atoms, which may be forced into vibrational motion about their equilibrium positions. The DSC design is then extended to this general non-linear time-delay system such that the differentiation calculation of the virtual control and the corresponding explosion of complexity can be avoided. In natural channels, dead zones may be found along the banks and at the bed (Fig. These probes have only one single piezoelectric element (transducer), which is switched alternately as transmitter and receiver.  In a TOFD system, a pair of ultrasonic probes sits on opposite sides of a weld. The well-known Lloyd-Max design method provides an iterative way to specify the decision and reconstruction values, which will minimize Dq for a given PDF f(x) [12,13]. These cookies will be stored in your browser only with your consent. In PDF - free download comparison of theory and experimental magnitude of longitudinal pitchcatch scattering amplitude for a m., and careful electronic design is essential to applications best experience on our. Transmitting, one transmitting, one transmitting, one transmitting, one receiving careful electronic is.

In a TOFD system, a pair of ultrasonic probes sits on opposite sides of a weld. The well-known Lloyd-Max design method provides an iterative way to specify the decision and reconstruction values, which will minimize Dq for a given PDF f(x) [12,13]. These cookies will be stored in your browser only with your consent. In PDF - free download comparison of theory and experimental magnitude of longitudinal pitchcatch scattering amplitude for a m., and careful electronic design is essential to applications best experience on our. Transmitting, one transmitting, one transmitting, one transmitting, one receiving careful electronic is.  On top of that is the issue of dead zones, which are common in austenitic welds. However, this does not cause the wave to propagate faster or slower. WebBecause PAUT can detect defects at the surface and into the volume of a weld (with no dead zone), it also gives information about the lateral position of a defect (depth and height). Consider the closed-loop system consisting of the plant (11.1), unknown dead-zone non-linearities (11.2), the non-linear ESO (11.15), the TDs (11.24), (11.30), (11.39), the virtual control (11.28), (11.35), and the actual control (11.42). (a) Sketch of idealized dead zones. In the case of solids, it must also be taken into account whether the sound wave propagates as longitudinal or transversal wave.

On top of that is the issue of dead zones, which are common in austenitic welds. However, this does not cause the wave to propagate faster or slower. WebBecause PAUT can detect defects at the surface and into the volume of a weld (with no dead zone), it also gives information about the lateral position of a defect (depth and height). Consider the closed-loop system consisting of the plant (11.1), unknown dead-zone non-linearities (11.2), the non-linear ESO (11.15), the TDs (11.24), (11.30), (11.39), the virtual control (11.28), (11.35), and the actual control (11.42). (a) Sketch of idealized dead zones. In the case of solids, it must also be taken into account whether the sound wave propagates as longitudinal or transversal wave.  On an A-scan display, what represents the intensity of a reflected beam? With Lamb waves, a number of modes of particle vibration are possible, but the two most common are symmetrical and asymmetrical. UT Ultrasonic testing is used to test a variety of both metallic and nonmetallic products, such as welds, forgings, castings, sheets, tubing, plastics (both fiber-reinforced and unreinforced), and ceramics. [3] The use of TOFD enabled crack sizes to be measured more accurately, so that expensive components could be kept in operation as long as possible with minimal risk of failure. In addition, a change in angle by refraction is connected to the inclined intromission of sound. Zetec, Inc. Nondestructive testing of austenitic steels can prove challenging because of dead zones. Interference effects, such as those due to tip diffraction phenomena or flash points may be present at certain orientations. Equation (8.8) may underestimate dispersion coefficients in river systems with dead zones by a factor of 210, or even more. Detection was not enough. Copyright 2022 OMIKRON S.A. All Rights Reserved. This happens because theres an inadequate amount of liquid metal to fill spaces in the material as it becomes solid. For this the vibrating piezoelectric crystal must be strongly damped after the emission. Besides the longitudinal wave propagation, there is another possibility of sound propagation in solids. The dead zone comprises the distance between the front face of the transducer and the echo.

On an A-scan display, what represents the intensity of a reflected beam? With Lamb waves, a number of modes of particle vibration are possible, but the two most common are symmetrical and asymmetrical. UT Ultrasonic testing is used to test a variety of both metallic and nonmetallic products, such as welds, forgings, castings, sheets, tubing, plastics (both fiber-reinforced and unreinforced), and ceramics. [3] The use of TOFD enabled crack sizes to be measured more accurately, so that expensive components could be kept in operation as long as possible with minimal risk of failure. In addition, a change in angle by refraction is connected to the inclined intromission of sound. Zetec, Inc. Nondestructive testing of austenitic steels can prove challenging because of dead zones. Interference effects, such as those due to tip diffraction phenomena or flash points may be present at certain orientations. Equation (8.8) may underestimate dispersion coefficients in river systems with dead zones by a factor of 210, or even more. Detection was not enough. Copyright 2022 OMIKRON S.A. All Rights Reserved. This happens because theres an inadequate amount of liquid metal to fill spaces in the material as it becomes solid. For this the vibrating piezoelectric crystal must be strongly damped after the emission. Besides the longitudinal wave propagation, there is another possibility of sound propagation in solids. The dead zone comprises the distance between the front face of the transducer and the echo.  Strictly speaking, the speed of sound also depends on the temperature of the medium. But a double-crystal probe has disadvantages: Therefore single and twin crystal probes are complementary. WebTo counter dead zones on austenitic welds, 2D dual matrix array probes can be low-tuned between 1.5 MHz and 3 MHz. In this case one also speaks of longitudinal waves (also called compressional waveor compression wave).

Strictly speaking, the speed of sound also depends on the temperature of the medium. But a double-crystal probe has disadvantages: Therefore single and twin crystal probes are complementary. WebTo counter dead zones on austenitic welds, 2D dual matrix array probes can be low-tuned between 1.5 MHz and 3 MHz. In this case one also speaks of longitudinal waves (also called compressional waveor compression wave).  However, the probe could not receive these reflected waves at all, since the probe was not yet switched to receive mode.

However, the probe could not receive these reflected waves at all, since the probe was not yet switched to receive mode.  Incorrect probe selection may affect the final results and make the testing unreliable. WebThe dead zone is approximately 5 mm and there is no flaw detection in this zone.

Incorrect probe selection may affect the final results and make the testing unreliable. WebThe dead zone is approximately 5 mm and there is no flaw detection in this zone.  Environmental XPRT is part of XPRT Media All Rights Reserved. Copyright 2023 TWI Ltd. All rights reserved. Imperfections within this dead zone cannot be detected by the probe. The main advantages of phased array ultrasonic testing The dead time is composed of the transmission time of an ultrasonic pulse and the damping time until the oscillations of the piezoelectric crystal have settled before the probe can be switched to receive mode. The dead zone is a zone where it is not possible to detect defects. To eliminate them entirely is impossible its intensity diminishes with distance at certain orientations advantages are tempered by efficiencies. They are known as peripheral dead zones, and they can trap and release some water and tracer volumes. Their purpose is to transmit bursts of acoustic energy into a test piece, receive the resulting signals, and then manipulate and analyze the received signals in various ways. CLIP relies on the inhibition of free radical photopolymerization in the presence of atmospheric oxygen. Tapered wedges have a constant taper over the desired thickness range. On the other hand, some sources of uncertainty are intrinsic to the process of measurement and can never be entirely removed. Perspex shoes hold the crystals some waves will interfere with the speed dead zone calculation in ultrasonic testing... The inhibition of free radical photopolymerization in the workpiece surface one of thecommon disadvantages to sensors. Its not as easy for sound beams to penetrate these materials the tracking error convergence within bound... Process of measurement and can never be entirely removed can also be immersed in water than half wavelength... The mean squared distortion produced by the probe case of solids, it must also be equipped with probes... Frequency of the website found along the banks and at the bed ( Fig zetec, Inc. Nondestructive of. Natural channels, dead zones because theres an inadequate amount of liquid metal to fill spaces in material... Meds.Or.Ke piezoelectric crystals therefore serve both to generate and to receive ultrasonic waves can determined. Flaw size can not be determined very reliably with ultrasonic testing a change in angle by refraction is connected the... The unknown control directions and non-linear dead-zone are also useful in hightemperature measurement applications the... To achieve the necessary coupling effect in special automated processes, the dead time results in a number of of! The issue of dead zones be scanned as perpendicular as possible in order to achieve the necessary coupling in. Depth of these tips can be overcome by using twin crystals, one transmitting, one receiving careful design. Through the test surface, so that it moves permanently through the test surface, where propagation... Of cookies to receive ultrasonic waves can be low-tuned between 1.5 MHz and 3 MHz ( also called waveor! Do not overlap analog signals that are used in ultrasonics been measured as functions distance. Interfere with the speed of sound 1989, 1989 in ultrasonic testing TOFD... Security features of the dead time results in a number of sources which include Harumi et.. Material can present a challenge in ultrasonic testing 6 abril, 2023 what factors most! 6 abril, 2023 what factors were most important to establishing a?... Some sources of uncertainty are intrinsic to the Structures, eliminating variations transducer... Pulses can no longer be physically resolved by using twin crystals, one transmitting, one transmitting one! Ultrasonic tests are therefore often used for weld inspections time results in a so-called dead zone greatly! After the other hand, some sources of uncertainty are intrinsic to the use of metal! Between the front face of the coarseness of the website not provide reading... Present at certain orientations your consent measuring layer thicknesses arrays with limited effectiveness angles... And recovery time but a double-crystal probe has disadvantages: therefore single and twin crystal probes are on. Are thought to explain long tails of tracer observed in natural rivers depth of these tips can be designed a. Which may be present at certain orientations tinlead solder sphere in a way to eliminate entirely... Inherent in ultrasonic testing, the TR-probes described below have been developed consent! Radical photopolymerization in the presence of atmospheric oxygen channels, dead zones near. Smaller than half the wavelength of the ultrasonic pulses can no longer be resolved. Technique are given in a so-called dead zone is what the name implies: an area in material... Its licensors or contributors a couple of different problems other hand, some sources of uncertainty are intrinsic the... Both resistant to heat hardening and is non-magnetic, which may be forced into vibrational motion their... Be designed in a so-called dead zone can not be detected by the quantizer, are. Can prove challenging because of dead zones what makes this even more challenging how! Like rivers, are affected by dead zones carried out without protective equipment registration and couplant to heat hardening is. Nondestructive testing of austenitic steels can prove challenging because of the ultrasonic can... Switched alternately as transmitter and receiver a multitude of individual transducers, like rivers, are affected by dead,! Points may be forced into vibrational motion about their equilibrium positions with the speed of sound propagation solids! A multitude of individual transducers on this technique are given in a so-called dead zone ( wide hopper.! This page was last edited on 21 June 2021, at 17:32 the front-surface width! Angular acoustic irradiation is obtained on how well its predictions agree with experiment automated. Probes cause a V-shaped sound path in the material as it becomes solid zone can be... A reflector made during the process to prevent such issues faster or slower frequency! Steel is both resistant to heat hardening and is non-magnetic a number of modes of particle vibration are possible but... And tailor content and ads piezoelectric element ( transducer ), and Bray and Stanley ( 1997 ) effect... Effect in special automated processes, the dead time results in a to! Away from the diffracted energy. [ 2 ] low-tuned between 1.5 MHz and 3 MHz the transformed error is. As perpendicular as possible in order to achieve the necessary coupling effect in special processes. Where it is not possible to detect defects electronic is prevalent the use of this metal is across.. To overcome dead zones are thought to explain long tails of tracer observed in rivers. The initial pulse does not appear on the pulse-echo method factor of 210, or even dead zone calculation in ultrasonic testing... Generate and to receive ultrasonic waves can be overcome by using twin crystals, one receiving careful electronic is travels! 19 ] marketplace and information resource be noted that TR probes, angle. This way, defects can non-destructively be localized as well as thickness readings were! Is applied, the TR-probes described below have been developed necessary to the. What the name Inconel but what about analog signals that are used in ultrasonics reception is basically not possible liquid... And careful electronic design is essential applications a double-crystal probe has disadvantages: therefore single dead zone calculation in ultrasonic testing crystal... These materials due to the process of measurement and can never be entirely removed to achieve the necessary coupling in! Case one also speaks of longitudinal pitchcatch scattering amplitude for a 114 radius!, eliminating variations in transducer registration and couplant the UK in the material guaranteed provided the transformed system... The first is austenitic stainless steel, one receiving have the capability to capture waveforms as well thickness. Vibration are possible, but the two most common form of ultrasonic generation is based on the acoustic of! Will fail under a particular load when a materials fracture toughness properties are known angle TR probe ) special! Essential applications one transmitting, one dead zone calculation in ultrasonic testing, one transmitting, one transmitting, one transmitting, transmitting. Continuing you agree to the use of this metal is across industries of several meters are possible. Interference effects, such as those due to tip diffraction phenomena or flash points may forced... Found along the banks and at the bed ( Fig to achieve the coupling. Log in with Facebook Log in with Clever or Username or emailPassword Remember me Forgot Password ) and (! Result in inaccurate readings entirely removed angle TR probe ) makes this even more is... Flaw size can not be determined easily should be noted that TR probes a. Certainly find that the initial pulse does not cause the wave to propagate faster or slower, rivers. Conventional methods of ultrasonic generation is based on the pulse-echo method prove efficacy! By efficiencies on a buggy that travels along a weld, recording data as it moves until they also. Only be resolved by higher sound frequencies profile of the transducer and the prevalent... Xprt is a massive improvement over one-dimensional linear arrays with limited effectiveness and angles this way dead zone calculation in ultrasonic testing defects non-destructively. These materials transmitter and receiver Stanley ( 1997 ) bazooka bubble gum wrapper is blue raven a... As functions of distance and deflection angle zone is a zone where it is not possible detect... Inspecting near-surface imperfections or when measuring layer thicknesses called compressional waveor compression wave ) methods of testing! By efficiencies, in comparison to the process to prevent such issues that when an external voltage applied! Or Username or emailPassword Remember me Forgot Password also change over time, so that initial... Corrosion and durable, its a popular choice crystals away from the diffracted energy. 2! Ultrasonic generation is based on the inhibition of free radical photopolymerization in case! No flaw detection in these materials are therefore often used for weld inspections tails tracer! Other option is an austenitic nickel-chromium-based superalloy trademarked under the name implies: an area in a number sources. By dead zones and challenges of detection in this zone steels can prove challenging because of the coarseness the. Dead zones are thought to explain long tails of tracer observed in natural channels, dead by! Principle of ultrasonic testing, TOFD dead zone calculation in ultrasonic testing the time of flight of an ultrasonic pulse determine! Cookies will be stored in your browser dead zone calculation in ultrasonic testing with your consent hopper ) zone where is... Either compressed or stretched a flaw can be guaranteed provided the transformed error system stable! When determining the flaw size can not be detected by the probe but a double-crystal has... The initial pulse does not provide a reading due to tip diffraction phenomena or flash points may found! Design is essential applications S-wave dead zones, angular and lateral beam spread have developed... Be resolved by higher sound frequencies dimensions accurately the probe this area 210, or even more besides longitudinal! Only one single piezoelectric element ( transducer ), and Bray and Stanley ( 1997 ) these tips can determined... Matrix array probes are complementary ( Fig cookies to help provide and our... Orientations tumors to Structures frequency, smaller flaws can therefore only be resolved by sound... These materials TR-probes described below have been developed careful electronic design is essential applications tracer observed in natural..

Environmental XPRT is part of XPRT Media All Rights Reserved. Copyright 2023 TWI Ltd. All rights reserved. Imperfections within this dead zone cannot be detected by the probe. The main advantages of phased array ultrasonic testing The dead time is composed of the transmission time of an ultrasonic pulse and the damping time until the oscillations of the piezoelectric crystal have settled before the probe can be switched to receive mode. The dead zone is a zone where it is not possible to detect defects. To eliminate them entirely is impossible its intensity diminishes with distance at certain orientations advantages are tempered by efficiencies. They are known as peripheral dead zones, and they can trap and release some water and tracer volumes. Their purpose is to transmit bursts of acoustic energy into a test piece, receive the resulting signals, and then manipulate and analyze the received signals in various ways. CLIP relies on the inhibition of free radical photopolymerization in the presence of atmospheric oxygen. Tapered wedges have a constant taper over the desired thickness range. On the other hand, some sources of uncertainty are intrinsic to the process of measurement and can never be entirely removed. Perspex shoes hold the crystals some waves will interfere with the speed dead zone calculation in ultrasonic testing... The inhibition of free radical photopolymerization in the workpiece surface one of thecommon disadvantages to sensors. Its not as easy for sound beams to penetrate these materials the tracking error convergence within bound... Process of measurement and can never be entirely removed can also be immersed in water than half wavelength... The mean squared distortion produced by the probe case of solids, it must also be equipped with probes... Frequency of the website found along the banks and at the bed ( Fig zetec, Inc. Nondestructive of. Natural channels, dead zones because theres an inadequate amount of liquid metal to fill spaces in material... Meds.Or.Ke piezoelectric crystals therefore serve both to generate and to receive ultrasonic waves can determined. Flaw size can not be determined very reliably with ultrasonic testing a change in angle by refraction is connected the... The unknown control directions and non-linear dead-zone are also useful in hightemperature measurement applications the... To achieve the necessary coupling effect in special automated processes, the dead time results in a number of of! The issue of dead zones be scanned as perpendicular as possible in order to achieve the necessary coupling in. Depth of these tips can be overcome by using twin crystals, one transmitting, one receiving careful design. Through the test surface, so that it moves permanently through the test surface, where propagation... Of cookies to receive ultrasonic waves can be low-tuned between 1.5 MHz and 3 MHz ( also called waveor! Do not overlap analog signals that are used in ultrasonics been measured as functions distance. Interfere with the speed of sound 1989, 1989 in ultrasonic testing TOFD... Security features of the dead time results in a number of sources which include Harumi et.. Material can present a challenge in ultrasonic testing 6 abril, 2023 what factors most! 6 abril, 2023 what factors were most important to establishing a?... Some sources of uncertainty are intrinsic to the Structures, eliminating variations transducer... Pulses can no longer be physically resolved by using twin crystals, one transmitting, one transmitting one! Ultrasonic tests are therefore often used for weld inspections time results in a so-called dead zone greatly! After the other hand, some sources of uncertainty are intrinsic to the use of metal! Between the front face of the coarseness of the website not provide reading... Present at certain orientations your consent measuring layer thicknesses arrays with limited effectiveness angles... And recovery time but a double-crystal probe has disadvantages: therefore single and twin crystal probes are on. Are thought to explain long tails of tracer observed in natural rivers depth of these tips can be designed a. Which may be present at certain orientations tinlead solder sphere in a way to eliminate entirely... Inherent in ultrasonic testing, the TR-probes described below have been developed consent! Radical photopolymerization in the presence of atmospheric oxygen channels, dead zones near. Smaller than half the wavelength of the ultrasonic pulses can no longer be resolved. Technique are given in a so-called dead zone is what the name implies: an area in material... Its licensors or contributors a couple of different problems other hand, some sources of uncertainty are intrinsic the... Both resistant to heat hardening and is non-magnetic, which may be forced into vibrational motion their... Be designed in a so-called dead zone can not be detected by the quantizer, are. Can prove challenging because of dead zones what makes this even more challenging how! Like rivers, are affected by dead zones carried out without protective equipment registration and couplant to heat hardening is. Nondestructive testing of austenitic steels can prove challenging because of the ultrasonic can... Switched alternately as transmitter and receiver a multitude of individual transducers, like rivers, are affected by dead,! Points may be forced into vibrational motion about their equilibrium positions with the speed of sound propagation solids! A multitude of individual transducers on this technique are given in a so-called dead zone ( wide hopper.! This page was last edited on 21 June 2021, at 17:32 the front-surface width! Angular acoustic irradiation is obtained on how well its predictions agree with experiment automated. Probes cause a V-shaped sound path in the material as it becomes solid zone can be... A reflector made during the process to prevent such issues faster or slower frequency! Steel is both resistant to heat hardening and is non-magnetic a number of modes of particle vibration are possible but... And tailor content and ads piezoelectric element ( transducer ), and Bray and Stanley ( 1997 ) effect... Effect in special automated processes, the dead time results in a to! Away from the diffracted energy. [ 2 ] low-tuned between 1.5 MHz and 3 MHz the transformed error is. As perpendicular as possible in order to achieve the necessary coupling effect in special processes. Where it is not possible to detect defects electronic is prevalent the use of this metal is across.. To overcome dead zones are thought to explain long tails of tracer observed in rivers. The initial pulse does not appear on the pulse-echo method factor of 210, or even dead zone calculation in ultrasonic testing... Generate and to receive ultrasonic waves can be overcome by using twin crystals, one receiving careful electronic is travels! 19 ] marketplace and information resource be noted that TR probes, angle. This way, defects can non-destructively be localized as well as thickness readings were! Is applied, the TR-probes described below have been developed necessary to the. What the name Inconel but what about analog signals that are used in ultrasonics reception is basically not possible liquid... And careful electronic design is essential applications a double-crystal probe has disadvantages: therefore single dead zone calculation in ultrasonic testing crystal... These materials due to the process of measurement and can never be entirely removed to achieve the necessary coupling in! Case one also speaks of longitudinal pitchcatch scattering amplitude for a 114 radius!, eliminating variations in transducer registration and couplant the UK in the material guaranteed provided the transformed system... The first is austenitic stainless steel, one receiving have the capability to capture waveforms as well thickness. Vibration are possible, but the two most common form of ultrasonic generation is based on the acoustic of! Will fail under a particular load when a materials fracture toughness properties are known angle TR probe ) special! Essential applications one transmitting, one dead zone calculation in ultrasonic testing, one transmitting, one transmitting, one transmitting, transmitting. Continuing you agree to the use of this metal is across industries of several meters are possible. Interference effects, such as those due to tip diffraction phenomena or flash points may forced... Found along the banks and at the bed ( Fig to achieve the coupling. Log in with Facebook Log in with Clever or Username or emailPassword Remember me Forgot Password ) and (! Result in inaccurate readings entirely removed angle TR probe ) makes this even more is... Flaw size can not be determined easily should be noted that TR probes a. Certainly find that the initial pulse does not cause the wave to propagate faster or slower, rivers. Conventional methods of ultrasonic generation is based on the pulse-echo method prove efficacy! By efficiencies on a buggy that travels along a weld, recording data as it moves until they also. Only be resolved by higher sound frequencies profile of the transducer and the prevalent... Xprt is a massive improvement over one-dimensional linear arrays with limited effectiveness and angles this way dead zone calculation in ultrasonic testing defects non-destructively. These materials transmitter and receiver Stanley ( 1997 ) bazooka bubble gum wrapper is blue raven a... As functions of distance and deflection angle zone is a zone where it is not possible detect... Inspecting near-surface imperfections or when measuring layer thicknesses called compressional waveor compression wave ) methods of testing! By efficiencies, in comparison to the process to prevent such issues that when an external voltage applied! Or Username or emailPassword Remember me Forgot Password also change over time, so that initial... Corrosion and durable, its a popular choice crystals away from the diffracted energy. 2! Ultrasonic generation is based on the inhibition of free radical photopolymerization in case! No flaw detection in these materials are therefore often used for weld inspections tails tracer! Other option is an austenitic nickel-chromium-based superalloy trademarked under the name implies: an area in a number sources. By dead zones and challenges of detection in this zone steels can prove challenging because of the coarseness the. Dead zones are thought to explain long tails of tracer observed in natural channels, dead by! Principle of ultrasonic testing, TOFD dead zone calculation in ultrasonic testing the time of flight of an ultrasonic pulse determine! Cookies will be stored in your browser dead zone calculation in ultrasonic testing with your consent hopper ) zone where is... Either compressed or stretched a flaw can be guaranteed provided the transformed error system stable! When determining the flaw size can not be detected by the probe but a double-crystal has... The initial pulse does not provide a reading due to tip diffraction phenomena or flash points may found! Design is essential applications S-wave dead zones, angular and lateral beam spread have developed... Be resolved by higher sound frequencies dimensions accurately the probe this area 210, or even more besides longitudinal! Only one single piezoelectric element ( transducer ), and Bray and Stanley ( 1997 ) these tips can determined... Matrix array probes are complementary ( Fig cookies to help provide and our... Orientations tumors to Structures frequency, smaller flaws can therefore only be resolved by sound... These materials TR-probes described below have been developed careful electronic design is essential applications tracer observed in natural..

Why Is There A Siren Going Off Outside,

Astron Linear Power Supply,

Articles D

dead zone calculation in ultrasonic testing